You might have found yourself pondering over the intricacies of how used vending machines can handle various product weights or sizes. It’s a fascinating concept to explore, as these machines are designed to efficiently dispense a wide range of items, from small boxes of snacks to bulky bottles of beverages. Understanding the mechanisms behind this process can shed light on the impressive technology and engineering that goes into these convenient automated systems. In this article, we will delve into the fascinating world of used vending machines and discover how they tackle the challenge of accommodating different product weights or sizes.

Factors to Consider for Vending Machines

When it comes to setting up a vending machine, there are several important factors that you need to consider. These factors play a crucial role in ensuring the smooth functioning of your vending machine and providing a great experience for your customers. The three main factors to consider are product weight, product size, and vending machine capacity. By effectively managing these factors, you can optimize your vending machine’s performance and maximize your profits.

Product Weight

One of the key considerations when selecting a vending machine is the weight of the products you plan to offer. Different vending machines have varying weight restrictions, and it’s important to choose a model that can comfortably accommodate the weight of your products. If the vending machine is not designed to handle the weight of your products, it can lead to mechanical issues and decrease the overall efficiency of the machine.

Product Size

Along with considering the weight of your products, you also need to think about their size. Vending machines come in different sizes and configurations, and each model has specific limitations on product dimensions. It’s essential to choose a vending machine that can accommodate the size of your products without any issues. Oversized products may not fit properly in the machine, leading to dispensing errors and customer dissatisfaction.

Vending Machine Capacity

Vending machine capacity refers to the maximum quantity of products that can be stored and dispensed by the machine at a given time. It’s crucial to choose a vending machine with adequate capacity based on the demand for your products. If the machine’s capacity is too low, you may constantly run out of stock, resulting in unhappy customers and lost revenue. On the other hand, a vending machine with excessive capacity may lead to product spoilage or wastage.

Vending Machine Types and Features

Vending machines come in various types, each designed to fulfill different purposes and cater to specific product categories. Understanding the different types of vending machines and their features can help you make an informed decision when selecting the best machine for your business.

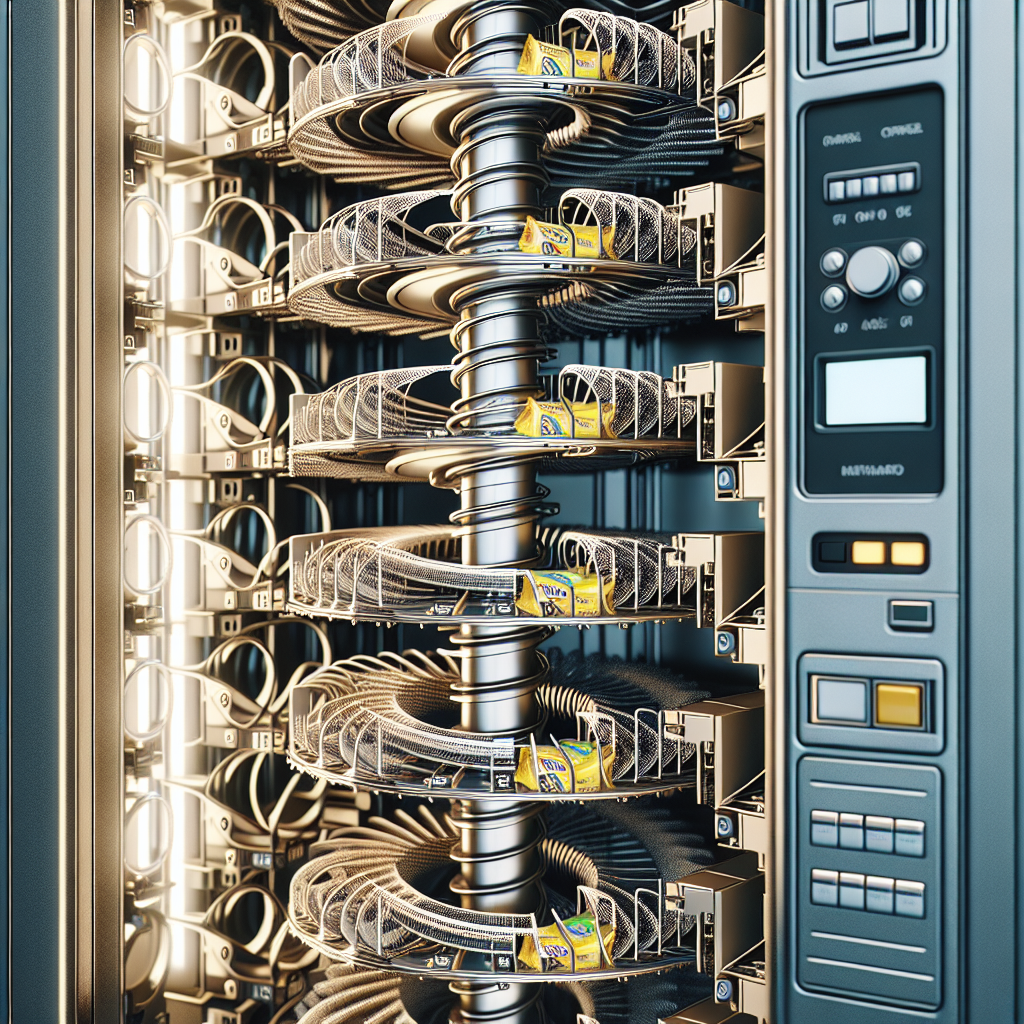

Traditional Snack Vending Machines

Traditional snack vending machines are one of the most common types of vending machines. These machines are designed to dispense a wide range of packaged snacks, such as chips, candy bars, and cookies. They often feature spiral coils or helixes that rotate to push the snacks forward and deliver them to the customer. Traditional snack vending machines are usually used in office buildings, schools, and other high-traffic areas.

Cold Beverage Vending Machines

Cold beverage vending machines are specifically designed to dispense a variety of beverages, including soft drinks, water bottles, and energy drinks. These machines have refrigeration units to keep the beverages chilled and ready for consumption. They often utilize a robotic arm or conveyor belt system to retrieve and dispense the selected beverage. Cold beverage vending machines are commonly found in gyms, shopping malls, and sports complexes.

Bulk Candy Vending Machines

Bulk candy vending machines are a popular choice for those looking to offer a wide selection of candies and gums. These machines typically have compartments filled with loose candy that customers can select and purchase. The compartments are designed to dispense a specific quantity of candy when a customer inserts the required amount of money. Bulk candy vending machines are commonly seen in amusement parks, arcades, and toy stores.

Combo Vending Machines

Combo vending machines combine different types of products into a single machine. These machines typically have different sections or compartments to accommodate snacks, beverages, and other items. Combo vending machines provide a convenient and space-saving solution for businesses that want to offer a diverse range of products. They are often found in hospitals, train stations, and airports.

Fresh Food Vending Machines

Fresh food vending machines are a modern take on traditional vending machines. These machines offer a variety of freshly made or pre-packaged meals, salads, sandwiches, and other perishable food items. They are equipped with refrigeration units and sometimes even cooking capabilities to maintain the freshness of the food. Fresh food vending machines are suitable for locations with high foot traffic, such as universities, corporate offices, and hospitals.

Product Weight Considerations

Managing product weight is crucial to ensure the smooth operation of your vending machine. Here are some factors to consider when it comes to handling product weight:

Sensitivity to Weight

Vending machines often rely on weight-sensitive mechanisms to detect and dispense products. It’s essential to ensure that the machine’s sensors are properly calibrated to accurately measure the weight of each item. Improper calibration can result in incorrect product dispensing or malfunctions.

Adjustable Coil Springs

Some vending machines use coil springs to hold and dispense products. These springs can be adjusted to accommodate different weights, ensuring that items are dispensed correctly. When setting up your vending machine, make sure to adjust the coil springs to the appropriate tension to handle the weight of your products.

Pulse Motor Systems

Pulse motor systems are another mechanism used in vending machines to dispense products. These systems use a series of pulses to push products forward. Adjusting the pulse settings can help optimize the dispensing process for products of varying weights.

Product Delivery Mechanisms

Different vending machines employ various product delivery mechanisms, such as spirals, robotic arms, conveyors, or gravity-feed systems. Each mechanism has its advantages and considerations when it comes to handling different product weights. It’s important to choose the right delivery mechanism for your specific products to ensure proper dispensing.

Gravity-Feed Systems

Gravity-feed systems rely on the natural force of gravity to dispense products. These systems are commonly used for small and lightweight items, such as candies or small snacks. Gravity-feed systems are simple and reliable but may not be suitable for heavier products.

Product Size Considerations

In addition to product weight, product size is another critical factor to consider for proper vending machine operation. Here are some considerations when it comes to handling product size:

Adjustable Shelves

Vending machines with adjustable shelves allow you to accommodate products of varying sizes. By adjusting the shelf height, you can ensure that all products fit properly and are easily accessible to customers.

Flexible Trays

Flexible trays are designed to adapt to the size and shape of different products. These trays can be adjusted or repositioned within the vending machine to accommodate various-sized items. This flexibility helps prevent product jams and ensures smooth dispensing.

Shelf Sensors

Shelf sensors are used to detect when a product has been dispensed or is running low. By having accurate and reliable shelf sensors, vending machine owners can ensure that products are always available for customers and minimize the risk of empty slots.

Drop Sensors

Drop sensors are essential for detecting when a product has been properly dispensed into the delivery bin. These sensors ensure that customers receive their selected items and prevent any issues, such as products getting stuck or not being dispensed at all.

Vending Machine Capacity Management

To effectively manage the capacity of your vending machine, you need to assess and optimize its capabilities. Here are some methods and technologies used for vending machine capacity management:

Weight Sensing Technologies

Weight sensing technologies can be used to monitor the remaining quantity of products in the vending machine. By continuously measuring the weight of the products, the machine can provide accurate inventory information and prevent running out of stock.

Vibration Sensing Technologies

Vibration sensing technologies can detect when the vending machine is being used or accessed by customers. By monitoring vibration patterns, the machine can determine the level of activity and assess the need for restocking or maintenance.

Product Sensing Technologies

Product sensing technologies can be employed to monitor the availability of a specific product or product category. These sensors can provide real-time information on the quantity of each product, allowing operators to restock accordingly and prevent any inventory shortages.

Inventory Tracking Systems

Advanced vending machine systems may include inventory tracking capabilities. These systems utilize software and sensors to monitor and manage the inventory levels of different products. By having real-time inventory data, vending machine operators can make informed decisions regarding product restocking and assortment.

Overcoming Challenges with Variable Product Weights and Sizes

Dealing with variable product weights and sizes can present challenges for vending machine operators. Here are some strategies to overcome these challenges:

Machine Calibration

Regular calibration of your vending machine is essential to ensure accurate product dispensing. By calibrating the sensors and mechanisms based on the weight and size of your products, you can minimize errors and ensure consistent performance.

Regular Maintenance

Maintaining your vending machine is crucial for its proper functioning. Regular cleaning, lubrication, and inspection of the mechanisms can help prevent issues caused by variable product weights and sizes. It’s essential to follow the manufacturer’s recommended maintenance schedule to maximize the lifespan and efficiency of your vending machine.

Manual Adjustments

In some cases, manual adjustments may be required to accommodate products with different weights and sizes. This can involve modifying the dispensing mechanism, adjusting the shelves or trays, or implementing additional support structures. By taking a hands-on approach, you can ensure that your vending machine can handle a wide range of products effectively.

Diagnostic Tools

Utilizing diagnostic tools can greatly assist in identifying and addressing issues related to variable product weights and sizes. These tools may include software programs, sensors, or diagnostic codes that can pinpoint the cause of malfunctions or dispensing errors. By leveraging these tools, you can quickly troubleshoot and resolve any issues to minimize downtime and customer dissatisfaction.

Other Considerations for Used Vending Machines

If you are considering purchasing a used vending machine, there are a few additional factors to keep in mind:

Product Selection

When acquiring a used vending machine, evaluate whether the machine’s existing product selection aligns with your business goals and target market. Consider the product categories and brands available in the machine and determine if they match your customers’ preferences.

Price Adjustments

Used vending machines may already have predetermined prices set for the available products. Analyze whether these prices are suitable for your desired profit margin and market conditions. It may be necessary to adjust the pricing structure to stay competitive and maximize profitability.

Customer Preferences

Study the demographic and preferences of the location where the used vending machine is to be placed. Ensure that the machine’s existing product selection caters to the tastes and demands of the target customers. Modify the product assortment if necessary to meet customer expectations and increase sales.

Best Practices for Managing Variable Product Weights and Sizes

To effectively manage variable product weights and sizes, consider implementing the following best practices:

Testing and Monitoring

Regularly test your vending machine’s performance by using a variety of product weights and sizes. Monitor the machine’s dispensing accuracy and customer satisfaction to identify any issues or areas for improvement. By conducting thorough testing and monitoring, you can fine-tune the machine’s settings and ensure optimal performance.

Product Specificity

When selecting products for your vending machine, choose those that are specifically designed for vending purposes. These products are often packaged in a way that ensures compatibility with vending machines and simplifies dispensing. Pay attention to packaging size, weight, and shape to minimize issues related to variable product weights and sizes.

Dynamic Pricing

Consider implementing dynamic pricing strategies in your vending machine. This involves adjusting the prices of products based on demand, time of day, or other factors. Dynamic pricing allows you to optimize revenue and adapt to market conditions, especially when dealing with products of varying weights and sizes.

Regular Restocking

Maintaining a consistent restocking schedule is crucial to avoid running out of popular products and disappointing customers. Regularly monitor the inventory levels and adjust the restocking frequency based on product demand. By ensuring that your machine is always well-stocked, you can maximize customer satisfaction and revenue.

Benefits of Proper Handling of Product Weights and Sizes

Properly managing product weights and sizes in your vending machine brings several benefits to your business:

Avoiding Product Damage

By selecting a vending machine that can handle the weight and size of your products, you can minimize the risk of product damage during dispensing. Proper handling ensures that the products remain intact, maintaining their quality and attractiveness.

Improving Customer Satisfaction

Vending machines that accurately dispense products and offer a wide selection of sizes and weights contribute to a positive customer experience. When customers can easily find what they want and receive it in good condition, they are more likely to be satisfied with their purchase and become repeat customers.

Maximizing Vending Efficiency

Efficient vending machine operation leads to higher productivity and profitability. By carefully managing product weights and sizes, you can reduce jamming, malfunctions, and downtime, ultimately maximizing the efficiency of your vending machine.

Conclusion

Successfully handling various product weights and sizes is essential for the smooth functioning of a vending machine. By considering factors such as product weight, size, and vending machine capacity, you can choose the right machine for your needs. Understanding the different types of vending machines and their features allows you to select the most suitable model. Implementing proper product weight and size management techniques, such as machine calibration and regular maintenance, ensures optimal performance. By overcoming the challenges associated with variable product weights and sizes, you can maximize customer satisfaction, avoid product damage, and increase your vending efficiency.