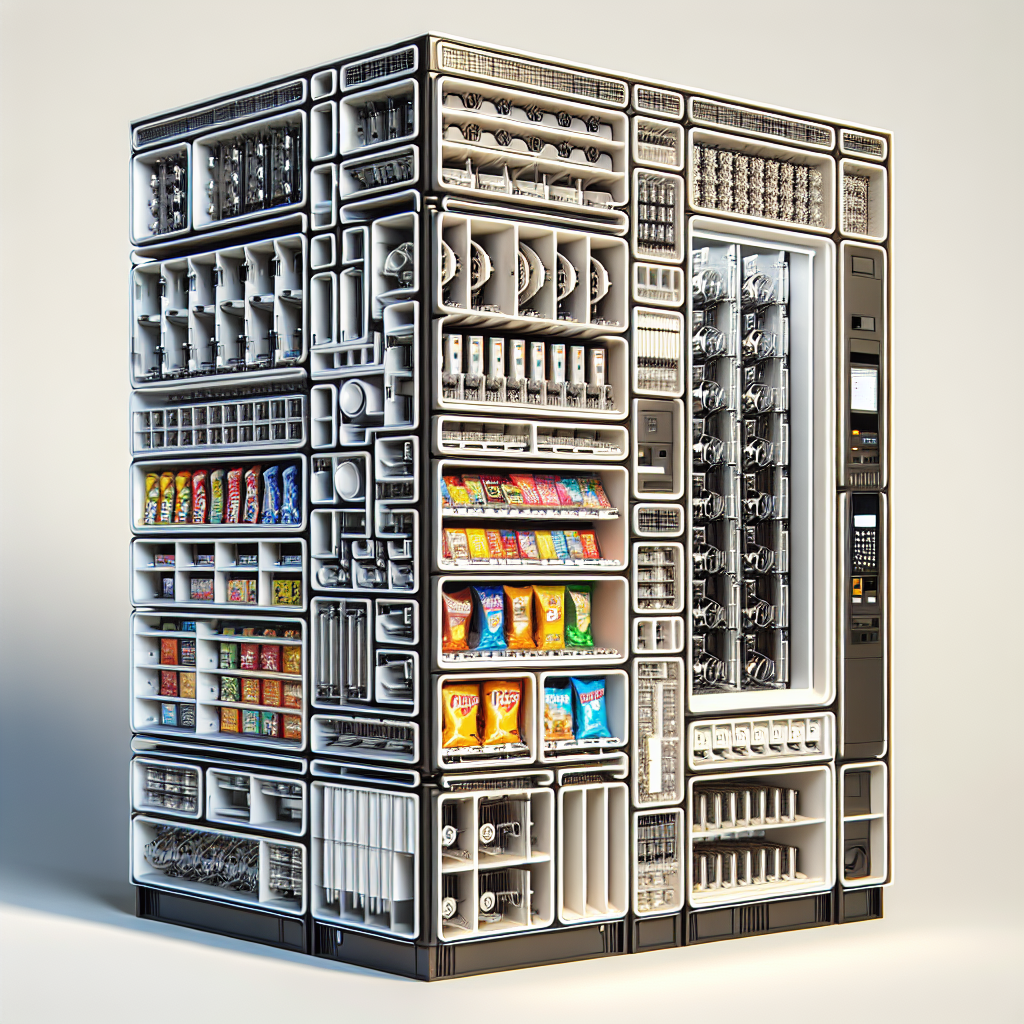

Imagine walking up to a combo vending machine, craving a snack or a cool drink. As you stand there, peering through the glass, you might wonder how exactly those machines can accommodate such a wide range of packaging sizes. From small bags of chips to bulky bottles, combo vending machines seem to have a magical ability to handle it all. In this article, we’ll uncover the clever mechanisms and ingenious design features that allow these machines to seamlessly serve up your favorite treats, no matter the packaging size. Get ready to be amazed by the inner workings of combo vending machines!

Overview

What are combo vending machines?

Combo vending machines are a type of vending machine that offers a variety of products, such as snacks, beverages, and even non-food items, in a single machine. These machines are designed to provide convenience and accessibility to consumers by offering a selection of products in one location.

Why are different packaging sizes a challenge?

Different packaging sizes can present a challenge for combo vending machines due to the limited space and the need to accommodate a range of product sizes. The unique shape, weight, and dimensions of various packaging sizes can make it difficult for the machine to properly handle and dispense the products. To overcome these challenges, combo vending machines employ various techniques and features that allow them to adapt to different packaging sizes.

Factors Influencing Handling of Different Packaging Sizes

Product Dimensions

The dimensions of a product, including its length, width, and height, play a crucial role in determining how it can be accommodated within a combo vending machine. Machines with adjustable shelving and dividers are able to accommodate products with varying dimensions, ensuring that each product is properly stored and dispensed.

Product Weight

The weight of a product is another important factor to consider when handling different packaging sizes. Combo vending machines are equipped with mechanisms that can support a wide range of weights, ensuring that both lightweight and heavier products can be stored and dispensed without any issues.

Packaging Material

The material used for the packaging also influences how combo vending machines handle different sizes. Machines with adjustable shelves and dividers that can securely hold products in place are essential for accommodating different packaging materials, such as glass bottles, cans, plastic containers, and snack pouches.

Adjustable Shelving

Combo vending machines utilize adjustable shelving to accommodate different packaging sizes. These shelves can be raised or lowered to create enough space for products of varying heights. This flexibility allows the machine to adapt to the specific dimensions of each product, ensuring that they are stored securely and easily accessible to the consumer.

Dividers and Spacers

In addition to adjustable shelving, combo vending machines may also incorporate dividers and spacers to assist in organizing and separating different packaging sizes. Dividers and spacers help to create distinct slots for products, preventing them from shifting or mixing together during transport or dispensing. This feature helps maintain the integrity and appearance of the products within the machine.

Product Configuration

Grouping Similar Sizes

One effective way combo vending machines handle different packaging sizes is by grouping products with similar sizes together. By clustering products with similar dimensions, the machine can optimize space and reduce the risk of products becoming dislodged or damaged during dispensing. This also allows consumers to easily locate the desired item within the machine.

Organizing by Weight

Another important factor in product configuration is organizing items by weight. Combo vending machines often have weight sensors or mechanisms that can determine the weight of each product. By categorizing products based on weight, the machine can ensure that the appropriate amount of force is applied when dispensing, preventing potential damage to fragile items or spillage of liquids.

Designating Special Slots

Combo vending machines may also have designated slots for products that have non-standard packaging sizes or shapes. Special slots can be customized to accommodate products that do not fit within the standard dimensions. This feature ensures that a variety of products can be offered in the machine, regardless of their unique packaging requirements.

Sensor Technology

Combo vending machines often incorporate sensor technology to ensure efficient handling of different packaging sizes. These sensors can detect factors such as package dimensions, weight, and material, allowing the machine to adjust its internal mechanisms accordingly. By utilizing advanced sensor technology, combo vending machines can accurately assess and respond to the specific packaging needs of each product.

Product Delivery and Drop System

Conveyor Mechanism

Combo vending machines may employ a conveyor mechanism to deliver products to the dispensing area. This mechanism is designed to transport products smoothly and efficiently, regardless of their packaging size. The conveyor system gently moves the products from the storage area to the dispensing area, ensuring that they arrive intact and ready for retrieval.

Elevator Mechanism

For taller or bulkier products, combo vending machines may utilize an elevator mechanism. This system lifts the products vertically to ensure they are easily accessible for retrieval. The elevator mechanism allows the machine to handle larger-sized items, such as bottles or multi-pack snacks, without compromising on the overall efficiency of the vending process.

Spiral Coil Mechanism

Combo vending machines can also feature a spiral coil mechanism for dispensing smaller items or products with unconventional shapes. These spiral coils rotate to propel the product towards the dispensing area, allowing for smooth and precise delivery. This mechanism works well for items like candy bars, small bags of chips, or even toys, ensuring that they are properly dispensed without getting stuck or damaged.

User Interface and Selection Process

Displaying Available Options

Combo vending machines utilize user-friendly displays to present the available options to consumers. These displays clearly show the different products and their corresponding packaging sizes, making it easy for users to select their desired items. Through clear and concise visuals, combo vending machines ensure that consumers can quickly identify and choose the right product for their needs.

Prompting for Packaging Sizes

Some combo vending machines prompt users to select the packaging size of the product they wish to purchase. This feature allows the machine to calibrate its internal mechanisms to accommodate the specific packaging requirements. By prompting for packaging sizes, the machine ensures that the dispensing process is tailored to each individual product, minimizing the risk of errors or mishandling.

Maintenance and Monitoring

Stock Monitoring

Combo vending machines are equipped with stock monitoring systems that track the inventory levels of each product. These systems can provide real-time updates on product availability, ensuring that the machine is always stocked with a variety of packaging sizes. By monitoring stock levels, operators can easily identify which items require restocking and plan accordingly.

Refilling and Restocking

To handle different packaging sizes effectively, combo vending machines require regular refilling and restocking. Operators must replenish the machine with products of various sizes to cater to the needs and preferences of consumers. Regular restocking ensures that the machine remains fully operational and can provide a diverse selection of items.

Servicing and Maintenance

Routine servicing and maintenance are essential to keeping combo vending machines in optimal condition. Regular inspections and cleaning help prevent malfunctions and ensure that the machine can handle different packaging sizes reliably. By prioritizing maintenance, operators can extend the lifespan of the machine and provide a seamless experience for consumers.

Conclusion

Combo vending machines are designed to handle different packaging sizes by employing various techniques and features. From adjustable shelving and dividers to sensor technology and advanced delivery systems, these machines adapt to the needs of different products. By ensuring proper handling, combo vending machines provide a convenient and efficient way for consumers to access a wide range of products.